When the word custom comes up in a design, it does not go unnoticed.

Describing a solution as ‘custom’ immediately gains attention due to the extra cost and time it implies, because it isn’t an ‘off the shelf’ product that is readily available. That assumption that it will require more effort, is true and sometimes detours the pursuit of a customization. With the current trend of compressed design phases and immediate construction deadlines it is even difficult for manufactures to keep up with standard product delivery. Suggesting a custom lighting fixture can come across as an obscenity, as if you just bluntly said that you want to waste time and money on the project.

In my design experience I have found some approaches that make customized lighting fixtures less offensive to the design process and ultimately benefiting the budget and project schedule. That doesn’t go without saying, be prepared for some frown lines, furrowed brows, and swearing either out loud or under your breath.

Do not lead with a custom design solution.

Try to reserve the custom design solution as a last resort and exhaust all other options. This will support the need that the custom fixture is necessary for the design vision.

Our project at Penn Mutual Towers, is a great example. With a historic presence the client wanted to update and refresh the building’s look to attract new tenants. The lobby experience needed to relate to today, but keep its historic context. At the 520 Walnut Entrance, where there are original decorative painted ceiling coffers, the design concept incorporated an open metal screen map walls. One wall would feature the original plan of Philadelphia and the opposing wall would feature the current map; the original marble walls would be visible beyond.

Our lighting solution was to backlight the 30 foot tall screens with linear LED products at the base of the walls and uplight the ceiling from the top. Unfortunately the entire wall design was value engineered from the project. With the lobby lingering, left undecided late in the design process and construction already underway, we scrambled with several options.

We developed custom sconce ideas however these did not produce the necessary uplight for the ceiling at the required mounting locations (covering holes and patches along the marble wall). Then we suggested a discrete, narrow profile wall mounted direct/indirect LED fixture mounted at the same location to cover the holes as opposed to patching. This solution turned out to be too glary with the reflective marble, despite suggestions of shielding and louvers. We abandoned the approach of lighting from the walls.

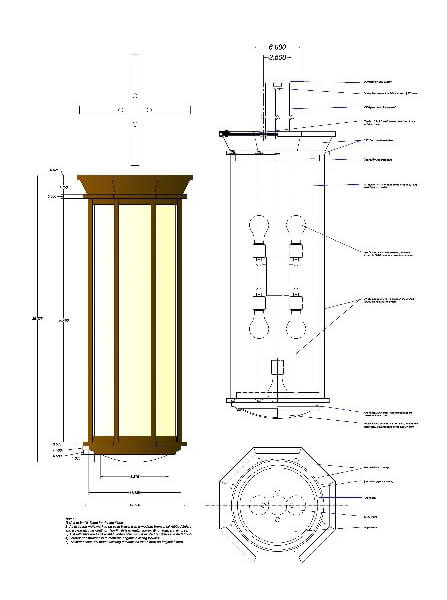

Ultimately the design solution was to create three replica fixtures of existing historic pendants (located in the adjacent corridor) and to add some additional downlights. The existing decorative historic fixtures had been taken down to be cleaned and refurbished, this offered the perfect opportunity to create a template from them for the new replicas. As a side note, this solution turned out to be less expensive than the wall mounted linear direct/indirect LED.

Be selective, don’t suggest custom fixtures all over a project.

Choosing the correct application to be custom will require some evaluation. A precedent for selection would be if a custom fixture is a key feature within the design.

We are lighting designers for an office high-rise project in Atlanta that has bands of fritted glass that run vertically at all floors and horizontally around the main training floor. The design solution was to light the bands from an edge, creating a luminous gasket. This luminous gasket will be the building façade’s hallmark creating an iconic landmark.

We proposed two options, both with linear LED fixtures. The first was to illuminate the gasket from the inside, indirectly lighting mechanized shades to illuminate the fritted glass. The second approach was to light the fritted glass from the exterior in continuous runs. It was decided that lighting façade gasket from the exterior was the best solution considering that the interior conditions weren’t consistent for the mechanized shade approach. To further investigate the idea there was an onsite mockup constructed. We found the reflection of the concealed luminaire, tight to the glass was extremely glary despite the asymmetric louver accessory that was added. We investigated, using a dimmer supplied for the mockup, what the optimal output would be to light the glass with minimal glare. However, we did not want to add the cost of a huge dimming system that would only be used for the exterior lighting.

We contacted the factory and asked if they could customize the thousands of feet of product by under driving the LEDs to the output measured at the mockup. This customization will be less than the cost of the dimming system installed to dim the output.

Assess the quantity.

In the end the number of fixtures you submit for customization or modification will affect the cost or even if the manufacture will provide the fixtures. The greater the quantity, the more reason for the investment to accommodate or create a customization, and consider retooling and resetting factory equipment. If the quantity is great enough it could just be a onetime cost adder to the order as opposed to a huge markup per fixture.

Another current project is the East Market, a new high-rise, mixed-use retail and residential development at Market Street, between 11th and 12th. The intention is to invest in the area and improve the streetscape experience to attract a better demographic along that stretch of Market Street.

The project is currently in its demolition phase with construction just around the corner and has entered a value engineering phase. With the strategy of investing in the façade and public areas we approached the cost savings by finding less expensive alternates to large quantities of fixtures. With about 300 residential units, the potential to reduce costs significantly could be applied by proposing a few alternates in the units.

The originally specified bathroom vanity fixture had an approximate distributor net cost $426.00. Our proposed alternate, very similar in look, dimensions and performance has an estimated cost of $230.00. However the bracket and end caps of this vanity fixture have branch detail cut outs with which the design team was not thrilled. So, this became one of those rare occasions were custom and value engineering (V.E.) actually worked together for a proposed solution! For a onetime adder of $100.00 the manufacture can modify the bathroom vanity sconces to the desired aesthetic while cutting the cost by about half.

The takeaway…

When it comes to custom fixtures and modifications, have a plan or strategy. Timeline and budget are key factors, but also consider quantity, lead time, material and finishes. Prepare some alternate options, and if possible get a few estimates for comparison. Overall, have information as backup to the typical reaction when Custom lighting fixtures come up in the design discussion.

*Lighting Lesson by Rochelle Spahn, former Associate with The Lighting Practice